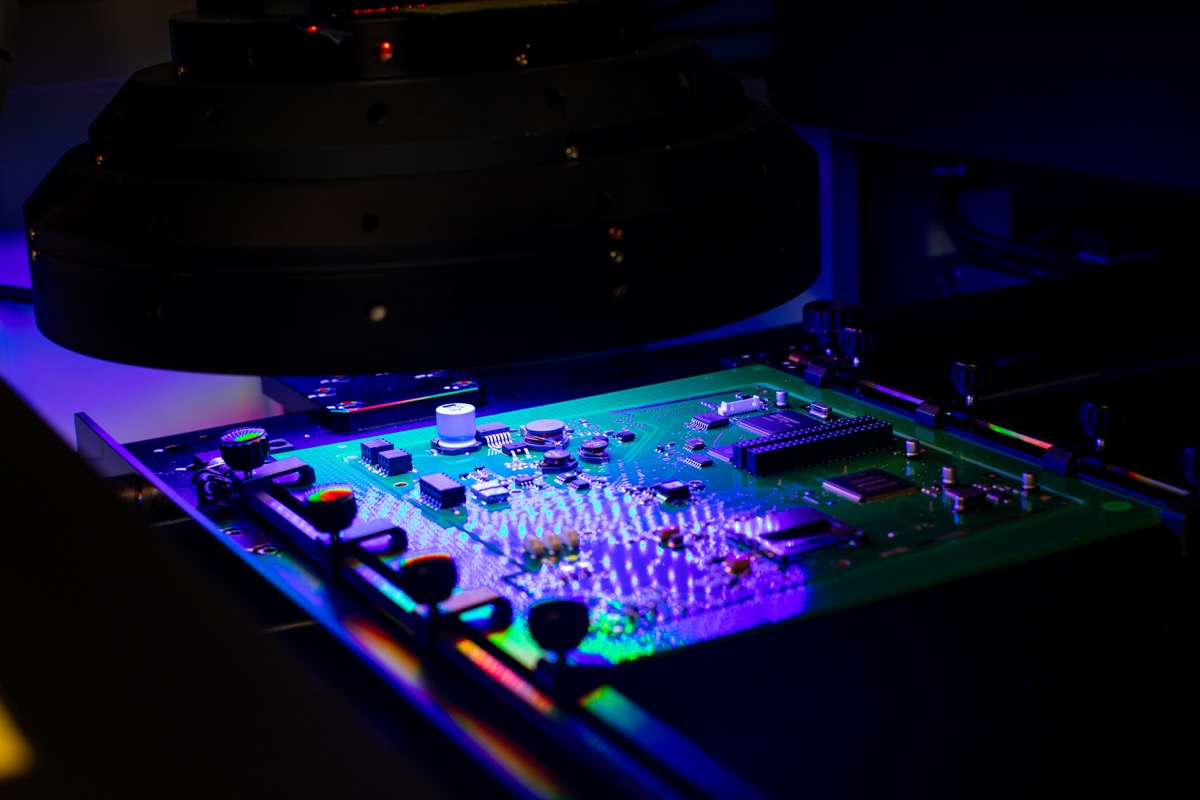

Turnkey PCB Assembly & Manufacturing

Full Turnkey PCB Assembly & Manufacturing Services: End-to-End Solutions for Seamless, High-Quality PCB Production

At MPE Electronics, we provide comprehensive full and partial turnkey PCB assembly solutions that take the responsibility of production off your shoulders.

From component sourcing to final assembly and testing, we handle every aspect of the process, ensuring a consistent, high-quality solution.

Our expert team works with you to simplify the manufacturing cycle, reduce complexity and eliminate the risks of managing multiple suppliers, so you can focus on what matters most – your product’s success. MPE’s turnkey PCB assembly solutions make your vision a reality, from prototype to high-volume production.

What is Turnkey Assembly?

Turnkey PCB assembly is a streamlined PCB assembly manufacturing solution where a single provider manages the entire process – from component sourcing to final assembly and testing. For engineers, product designers and sourcing managers, this means a smooth workflow with fewer supply chain headaches and faster time to market.

With turnkey PCB assembly, contract electronics manufacturers take care of procurement, component placement, soldering, quality control, testing, as well as packaging and logistics. This eliminates the complexity of coordinating multiple suppliers, ensuring that every part of the process aligns with the required specifications.

Whether you’re designing a high-reliability medical device, a precision automotive PCB or a complex industrial controller, turnkey PCB assembly ensures consistent quality and traceability.

Turnkey Assembly vs Full Box Build

Turnkey PCB assembly and full box build serve different needs in the electronics manufacturing process.

Turnkey PCB assembly focuses on producing fully populated circuit boards. The provider handles everything from component sourcing to assembly, soldering and testing. This is ideal for engineers and product teams looking for a hassle-free solution that delivers tested, production-ready boards without managing multiple suppliers.

Full box build extends beyond PCB assembly. It includes enclosure integration, cable harnessing, final product assembly and even packaging. If your project requires fully assembled electronic devices ready for end-use deployment, a full box build service or our bespoke PCB assembly might be the better choice.

For many product designers and sourcing managers, turnkey PCB assembly strikes the right balance between efficiency and control. It allows you to focus on innovation while your manufacturing partner ensures high-yield, defect-free production. If enclosure integration and final assembly are part of your requirements, full box build is a logical next step.

Benefits of Turnkey Assembly

Turnkey PCB assembly provides significant advantages for engineers, product designers and sourcing managers aiming to optimise production, reduce costs and ensure product quality.

- Simplified Supply Chain – A single provider handles component sourcing, PCB assembly and testing, reducing complexity and procurement risks

- Cost Efficiency – Bulk purchasing, supplier relationships and inventory management help lower manufacturing costs and prevent component shortages

- Quality Assurance – Enhanced inspections like AOI, X-ray for BGA components and functional testing ensure high reliability and compliance with industry standards

- Faster Time to Market – Integrated processes and fewer supply chain bottlenecks allow quicker transitions from prototyping to full-scale production

- Scalability – Easily transition from small-batch prototyping to high-volume production with consistent quality and efficiency.

For those developing high-performance electronic products, turnkey PCB assembly offers an efficient, scalable and quality-driven manufacturing solution.

Our Turnkey PCB Assembly Services

Choosing the right turnkey PCB assembly partner is critical to product success. MPE’s turnkey services go beyond assembly – we provide expert guidance on design for manufacturability (DFM) and component selection and sourcing to enhance efficiency and reliability.

With industry experience across automotive, medical, industrial and aerospace, among others, we understand the unique challenges of high-performance PCB production. Our team ensures compatibility, compliance and consistency, whether for a prototype or large-scale manufacturing.

We work closely with engineers and sourcing managers to anticipate potential production bottlenecks, reduce lead times and mitigate risks. By leveraging our extensive supplier network and in-house expertise, we help you achieve a faster, more resilient manufacturing process that supports innovation and scalability.

From the moment you partner with MPE, you’ll have a dedicated project manager overseeing your PCB assembly journey, ensuring all milestones are met and communication stays clear. We guide you through each stage – from design consultation to final delivery – making the process easy and hassle-free.

Partial Turnkey PCB Assembly

For customers who want control over sourcing, our partial turnkey PCB assembly service allows you to supply some components while we handle assembly, testing and quality assurance.

Component Verification & Inventory Management – We inspect incoming parts for authenticity, quality and accuracy, managing overages and shortages to prevent production delays

Precision PCB Assembly – Using Surface Mount (SMT) and Through-Hole (THT) technologies, we ensure high-accuracy component placement and soldering

Testing & Inspection – We perform Automated Optical Inspection (AOI) and functional testing to ensure quality and performance

Packaging & Logistics – Safe anti-static packaging, labeling and shipment coordination for on-time delivery.

With partial turnkey, you maintain oversight of key components while we manage the complexities of manufacturing.

Full Turnkey PCB Assembly

For a fully managed production process, our full turnkey PCB assembly service covers everything from sourcing to final delivery, minimising supply chain complexity and lead times.

Component Sourcing & Procurement – We source from trusted suppliers, managing inventory, overage control and counterfeit prevention for a seamless supply chain

PCB Assembly (SMT & THT) – High-precision placement, reflow soldering, wave soldering and selective soldering for optimal reliability

Quality & Testing – includes Automated Optical Inspection (AOI) and functional testing to ensure quality and performance

Final Assembly & Logistics – Custom labeling, serialisation and secure global shipping for a hassle-free delivery process

Scalable Production – Seamless transition from prototyping to high-volume manufacturing with quality control.

Full turnkey assembly reduces lead times, lowers costs and eliminates risks like component shortages or counterfeit parts, providing a seamless path from prototype to production.

Which turnkey assembly service do you need?

Choosing between partial and full turnkey PCB assembly depends on your project requirements, budget and required level of control.

Partial Turnkey: Best if you want to supply some components or manage procurement while outsourcing assembly and testing. Ideal for projects needing custom or specialised parts.

Full Turnkey: The most efficient and hassle-free option, with all aspects of manufacturing handled by us, ensuring faster production, cost savings and strict quality control.

Not sure which suits your project best? Contact us to discuss your requirements, and we’ll help you choose the most efficient and cost-effective assembly solution.

Why MPE Electronics is the Perfect Choice for Your Turnkey Solutions:

Our Capabilities

MPE Electronics is your ideal partner for turnkey PCB assembly solutions, offering a unique blend of expertise and capabilities to bring your projects to life:

From prototyping to high-yield production: We seamlessly scale your project from early-stage prototypes to high-volume, high-reliability production, ensuring consistent quality at every step

Design for Manufacturability (DFM): Our experts optimise your designs early in the process to ensure cost-effective, efficient and reliable manufacturing

Comprehensive testing: We offer rigorous functional, electrical and quality testing to guarantee that your PCB assemblies meet the highest performance standards and your specifications.

Full range of PCBs: Specialising in flexible, rigid and rigid-flex PCBs, we deliver solutions tailored to your specific application needs.

Our Certifications

At MPE Electronics, we adhere to the highest industry standards, ensuring that every PCB assembly project meets rigorous quality and regulatory requirements.

ISO 9001 Certification: Ensures consistent, high-quality processes and management systems across all stages of production

IPC-A-610 Standards: Guarantees our assemblies meet the highest standards for PCB acceptability in terms of quality and reliability

RoHS Compliance: Confirms that our PCBs are free from hazardous materials, aligning with environmental regulations and supporting your sustainability goals.

Came KMS & MPE Electronics: A Case Study

Came KMS has relied on MPE Electronics for turnkey PCB assembly services since 2014. MPE provides complete solutions, handling everything from assembly to potting, testing and programming, ensuring Came KMS’s access control systems are built to exact specifications.

A key part of the partnership has been MPE’s ability to support Came KMS’s needs throughout challenges such as the 2019 pandemic and resulting global component shortages:

“We have worked with MPE for many years and formed a close working relationship to secure a reliable supply of electronic components. Over that time, MPE has remained a strong partner, providing excellent products and service. The team at MPE are open, direct and flexible, helping us meet the ever-changing demands of our customers.”

Came KMS

Selecting the right turnkey PCB assembly partner is crucial for streamlining your production process and achieving reliable, high-quality results. At MPE, we take care of every aspect – from component sourcing to final testing – so you can focus on advancing your product. Our team works closely with you to deliver tailored turnkey solutions that reduce risks, cut lead times and meet your design, cost and performance goals. Ready to simplify your next project? Let’s connect and make your vision a reality.

WE’RE HERE TO HELP

If you’re looking for a PCB supplier, ready and prepared to adapt to your specific or changing needs, please contact us at

FAQs About Turnkey Assembly

Which industries benefit most from Turnkey Assembly services?

Turnkey assembly services benefit a wide range of industries, including electronics, automotive, medical, telecommunications, military and defence. These sectors rely on high-quality, cost-efficient production, fast turnaround and precise component integration. Turnkey services streamline the process, from component sourcing to final assembly, making them ideal for complex designs, high-volume production and rapid prototyping. Request a Quote Today!

Which types of products can MPE Electronics assemble using Turnkey solutions?

MPE Electronics can assemble a wide range of products using turnkey assembly solutions, including medical devices, automotive components, industrial controls and telecommunication equipment. We specialise in complex assemblies, from PCBs and flexible circuits to high-precision assemblies for niche applications. Our turnkey services ensure seamless integration, high-quality standards and customised solutions for both low-volume prototyping and high-volume production.

Can I provide my own components for Turnkey PCB Assembly?

Yes! We offer both full and partial turnkey solutions. For partial turnkey, you can provide some components while we handle the assembly, testing and quality control. This gives you flexibility in sourcing your preferred parts while simplifying the rest of the process.