Guide To PCB Soldering

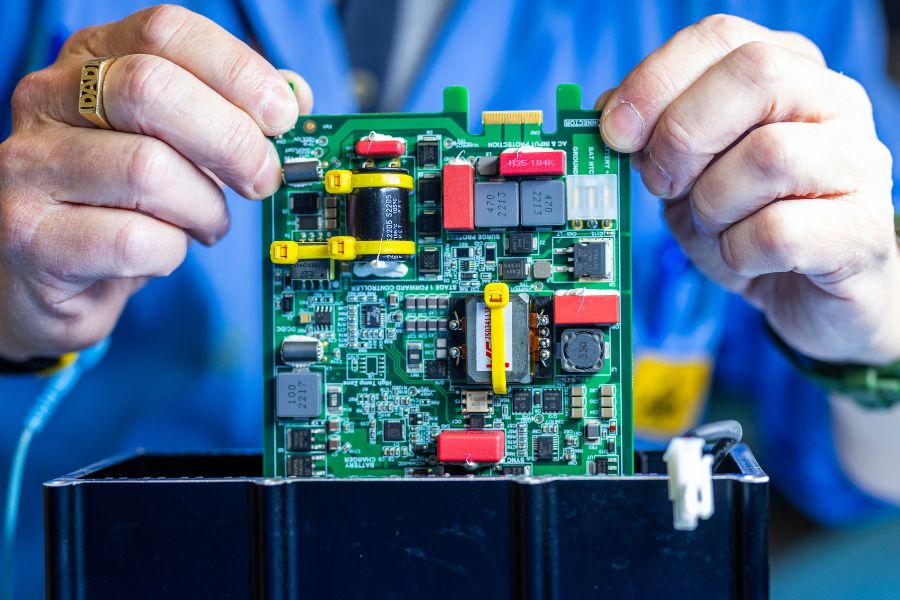

PCB soldering is a critical process in electronic manufacturing that involves attaching electronic components to a printed circuit board using solder. There are two types of soldering processes available – wave soldering and hand soldering.

Wave soldering uses a dedicated machine for conventional through-hole mounted components which can be programmed to produce joints that are mechanically and electrically reliable, while hand soldering is as described – a soldering process carried out by an experienced human hand.

In this guide, we explore the instances in which hand soldering can be the most effective option for your PCB manufacturing, the differences between wave soldering and hand soldering and the ways to ensure it is done correctly.

Reasons To Choose Hand Soldering

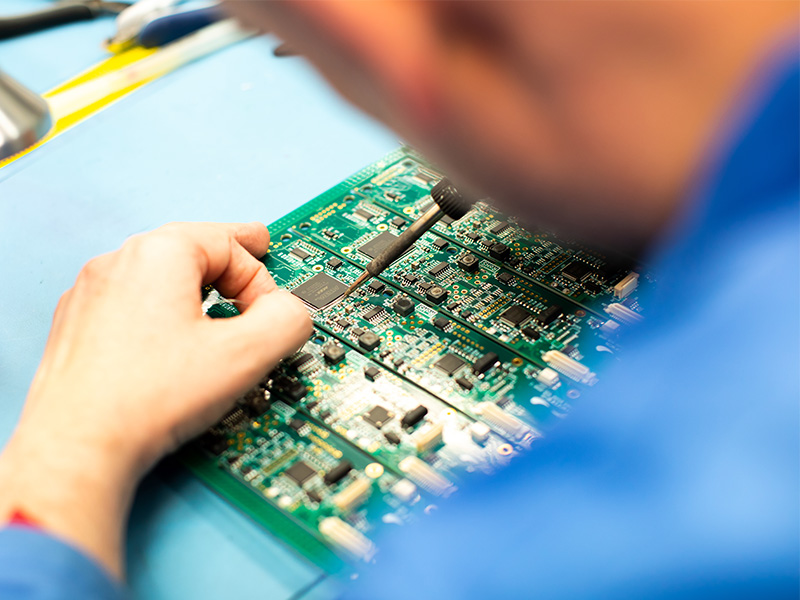

Hand soldering should be carried out manually by highly trained and experienced soldering experts who possess the skill, precision and knowledge of industry standards to ensure reliable connections.

It is used on components that cannot, or should not, be wave soldered, for example, if greater flexibility and precision is needed, the PCB has surface mounted components on both sides, or it is the more efficient way of getting the job done, because setting up the machine would be more time consuming and costly. (This can happen in cases where a small number of units are involved).

Hand soldering is a flexible option to use as the technician solders each component separately and can use different solder tips as and when they are required. Essentially, using this method allows for last minute changes to be made without needing to reset the machine.

MPE Electronics technicians have the ability to choose a soldering iron and different size nibs to suit the components being hand soldered. Some soldering applications require precision soldering and only experienced personnel can make decisions on the best type of solder tip or technique to use for each part of the work, whether the solder is placed correctly for the component or wire, or if adjustments or corrections are required.

8 Steps To Optimal Hand Soldering

The MPE Electronics soldering experts have the following step-by-step tips for optimal PCB hand soldering from start to finish:

Prepare the workspace

Ensure that the workspace is clean, ESD controlled, well-lit, and free from distractions. Gather all necessary tools and materials, including a soldering iron, solder, flux, tweezers, and a PCB holder. Adhere to workplace safety guidelines when setting up the workspace.

Verify the soldering equipment

Verify that the soldering iron and other equipment are calibrated and set to the appropriate temperature for the type of solder and components being used. Use temperature-controlled soldering irons to achieve precise control over the soldering process.

Apply flux

Flux is used in this hand soldering process to clean the metal surfaces. This prevents oxidation during the hand soldering. Apply flux to the area where the component will be soldered. Use only the recommended amount, as excess flux can damage the PCB. Ensure that the flux used is compliant with industry standards.

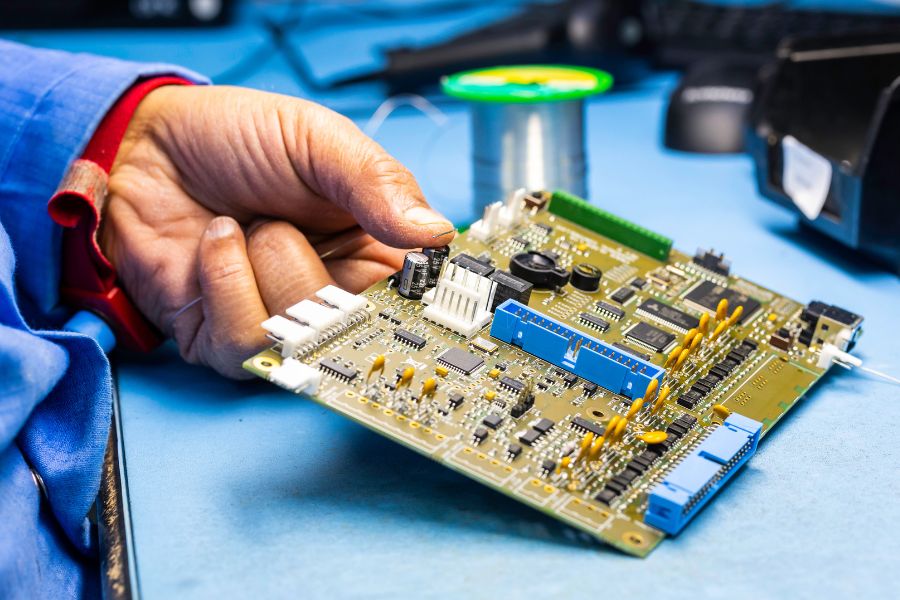

Place the component

Use tweezers to place the component onto the PCB if needed (this is dependent on the type of component being soldered). Ensure that the component is properly oriented and aligned with the other components.

Solder the joints

Place the tip of the soldering iron onto the joint where the component meets the PCB. Heat the joint for the appropriate length of time and then touch the end of the solder to the joint. The solder should flow through the hole (a minimum of 75% flow through) then flow around the joint.Avoid overheating the joint, as this can cause damage to the component or the PCB.

Inspect the joint

Once the joint has cooled, inspect it to ensure that it meets current standards. If the joint appears dull or lumpy, it may be cold and require re-soldering.

Repeat the process

Continue to place and solder the remaining components, working from the smallest to the largest components. Ensure that each component is soldered according to industry standards.

Clean up

After soldering, clean up any excess solder or flux residue using a solder wick or flux remover. Adhere to workplace safety guidelines when handling hazardous materials.

PCB Soldering Standards and Guidelines

It’s vital that you adhere to industry standards and guidelines when soldering PCBs. By following the steps above, you can ensure that your soldered connections are reliable and meet stringent industry standards.

The industry standards for hand soldering of PCBs in the UK are set by the Institute of Printed Circuits (IPC) and are widely recognised and followed by professionals in the electronics industry.

These standards cover various aspects of the soldering process, including the use of materials, equipment, and soldering techniques. Some of the most relevant IPC standards for hand soldering of PCBs in the UK include IPC-A-610.

This standard covers the acceptability criteria for electronic assemblies, including the visual inspection of solder joints and other components to ensure they meet the requirements for reliability and functionality. All factory staff at MPE Electronics are IPC-A-610 certified.

Adherence to IPC standards is essential for ensuring that hand-soldered PCBs meet the required levels of quality and reliability. It’s important for professionals in the electronics industry in the UK to stay up-to-date with the latest IPC standards and guidelines to ensure that their work meets industry requirements.

Knowing which soldering method is best suited to your PCB assembly and having the steady-handed, highly trained and knowledgeable technicians to carry it out is something MPE prides itself on.

Get in touch with a member of our team today to discuss your PCB soldering requirements.

We’re here to help

If you’re looking for a PCB supplier, ready and prepared to adapt to your specific or changing needs, please contact us at

PCB Assembly

Precise, reliable PCB assembly to your exact requirements.

Box Build Assembly

Optimise your supply chain with our turnkey assembly service.