Conventional PCB Assembly

Conventional PCB Assembly Services for Precision, Reliability and Performance

At MPE Electronics, we recognise that every connection matters.

Purchasing professionals, designers and electronics engineers are often under pressure to deliver products that not only meet stringent performance requirements but also ensure reliability and durability across a wide range of environments. Whether it’s balancing cost-effectiveness, meeting tight deadlines or tackling complex design requirements, the challenges are numerous.

That’s where MPE Electronics steps in. Our conventional PCB assembly service has been designed with an unwavering focus on quality, efficiency and customisation.

Our conventional THT (through-hole technology) assembly process ensures robust, long-lasting performance, making it ideal for applications where mechanical strength and durability are crucial. From product prototypes to final production, we provide a seamless experience, leveraging our team of experts to deliver exceptional results – no matter how complex your design is.

What is Conventional PCB Assembly?

Conventional PCB assembly refers to the process of manually soldering components onto a printed circuit board (PCB) using traditional methods. Unlike automated surface mount technology (SMT), conventional assembly typically involves through-hole technology (THT) where components with leads are inserted through holes in the board and soldered manually.

This method is ideal for components that require more mechanical strength and reliability, particularly in environments where durability is critical.

At MPE, we combine conventional PCB assembly with a high level of precision, ensuring your designs are brought to life exactly as intended.

Conventional Assembly vs THT: Which Do You Need?

Conventional Assembly and Through-Hole Technology are often used interchangeably, but they serve different purposes depending on your design requirements. The key difference lies in the method of component attachment and the nature of the components themselves.

Conventional Assembly involves the insertion of both leaded and surface-mounted components, usually in low to medium-volume runs. This method is best suited for designs requiring a mix of component types and specific manual interventions.

THT (Through-Hole Technology) is used for components that require stronger physical connections, like heavy-duty connectors or components exposed to higher stress. THT is often preferred in products that need exceptional mechanical stability and durability.

What’s included in our Conventional PCB Assembly Service

Our conventional PCB assembly service is comprehensive, providing everything you need to bring your design from concept to finished product:

Component Sourcing & Inventory Control: We help you source high-quality, reliable components

Soldering: Both manual and machine soldering to guarantee reliable joints

Inspection & Testing: Extensive inspection and testing to ensure functionality & reliability

Packaging & Shipping: Safe & secure packaging to ensure products are delivered on time

At each stage of production, our conventional PCB assembly service ensures your products meet industry standards and exceed expectations.

What are the benefits of selecting Conventional PCB Assembly?

Conventional PCB assembly offers several key advantages that make it an ideal choice for a wide range of applications, especially where reliability and durability are paramount. These include:

Enhanced Durability: Ideal for designs that need stronger physical connections, such as industrial, automotive or medical devices

Superior Reliability: Ensures more robust and mechanically stable connections that withstand environmental challenges, improving the long-term performance of the final product.

Cost-Effective for Prototypes: Offers an efficient, lower-cost assembly solution for prototypes or short-run production without compromising quality.

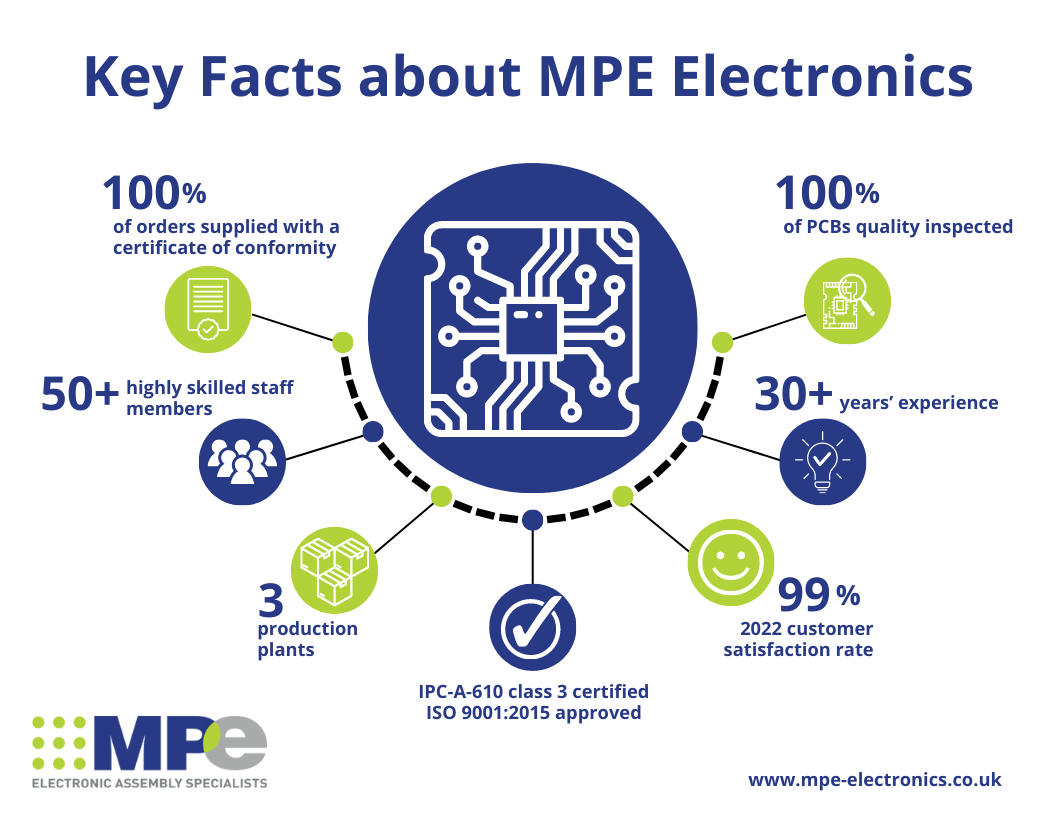

Why Choose MPE Electronics for Your Electronics Manufacturing Needs?

At MPE, we recognise the unique pressures faced by purchasing teams, PCB designers, and electronics engineers. Our conventional PCB assembly services are designed to provide a seamless experience from start to finish.

Our Capabilities

High-Mix, Low-to-Medium Volume Production: Flexibility to support prototyping and scaling without sacrificing quality or cost-efficiency

Advanced PCB Assembly: From complex multilayer designs to highly customised assemblies, we deliver solutions for every need

End-to-End Project Management: We handle every step, from initial manufacture for design verification to final delivery, ensuring that you can focus on innovation and design while we take care of the manufacturing

Comprehensive Testing: We test all assemblies according to customer specification, including functional, environmental and stress tests, to ensure long-term reliability in the field.

Our Certifications

We hold the highest industry standards, ensuring that your projects comply with all regulations:

ISO 9001 Certification: Maintaining quality systems across all stages of production

RoHS Compliance: Environmentally friendly manufacturing processes that meet all regulatory requirements

Delivering Precision and Flexibility in High-Mix, Low-to-Medium Volume PCB Assembly: A Case Study

MPE successfully delivered reliable, high-quality assemblies for a leading analytical instrumentation provider. Specialising in high-mix, low-to-medium volume production, we tailored our approach to meet the customer’s complex requirements. As a result, the customer was able to achieve consistent performance across their instrumentation, with precision and flexibility in production. This partnership highlights MPE’s ability to adapt to demanding conditions and deliver reliable solutions for critical applications.

“We chose to work with MPE in 2013 as we were looking for a local company with a good reputation. Since then, MPE has created an assembly solution for us that provides on time deliveries for 100-plus product variants on a monthly basis at a competitive price with high standards of service.”

FAQs About Conventional PCB Assembly

Is Conventional Assembly right for your needs?

Conventional PCB assembly is ideal for projects requiring strong mechanical connections, complex designs or components with larger leads. It’s perfect for low-to-medium volume production where durability, flexibility and precision are essential, particularly for products exposed to mechanical stress or harsh environments.

What types of products are best suited for Conventional PCB Assembly?

Conventional PCB assembly is best suited for products in industries like automotive, medical devices, industrial control systems and aerospace. It’s perfect for designs that require robust, stable connections for components under high stress, such as connectors, relays or heavy-duty components.

What is the typical turnaround time for Conventional PCB Assembly?

The typical turnaround time for conventional PCB assembly depends on the complexity and volume of the project but generally ranges from 2 to 6 weeks. Factors such as component availability, testing requirements and production complexity can affect the timeline.

What’s the difference between THT, SMT and Conventional Assembly?

THT (Through-Hole Technology) involves inserting components with leads through the PCB and soldering them, providing strong mechanical connections. SMT (Surface-Mount Technology) places components directly on the PCB surface, ideal for high-volume, automated assembly. Conventional Assembly typically combines both methods, used for low-to-medium volume, complex designs requiring robust, durable connections.

Choosing the right conventional PCB assembly partner means selecting a company that understands your unique challenges. At MPE, we focus on providing solutions that streamline your process, reduce risks and guarantee reliable, high-quality results. Our team works alongside you every step of the way, offering tailored solutions to help you meet your design, cost and performance goals.

WE’RE HERE TO HELP

If you’re looking for a PCB supplier, ready and prepared to adapt to your specific or changing needs, please contact us at