Through Hole Assembly

Achieving strong connections

with Through Hole Assembly

Enhanced strength and security make Through Hole Technology (THT) PCB assembly the preferred option for electronic products requiring larger componentry, where a more robust mechanical bond between the circuit board and the components is essential. Typical THT PCB assemblies include transformers, connectors, semiconductors, and electrolytic capacitors.

Through Hole assembly, where pre-formed leaded components are threaded through pre-drilled holes, which are then soldered directly onto circuit boards, offers a number of benefits, including the ability to:

Endure environments with high levels of stress

Operate at high speeds

Reliably perform in extreme temperatures, both hot and cold

Function in high-voltage conditions

Fast and straightforward prototyping is also made possible because the components can be readily adjusted or replaced prior to soldering.

As with Surface Mount Technology (SMT), components can be mounted on both sides of the board.

Mixed Technology Assembly

& Multi-Layer PCBs

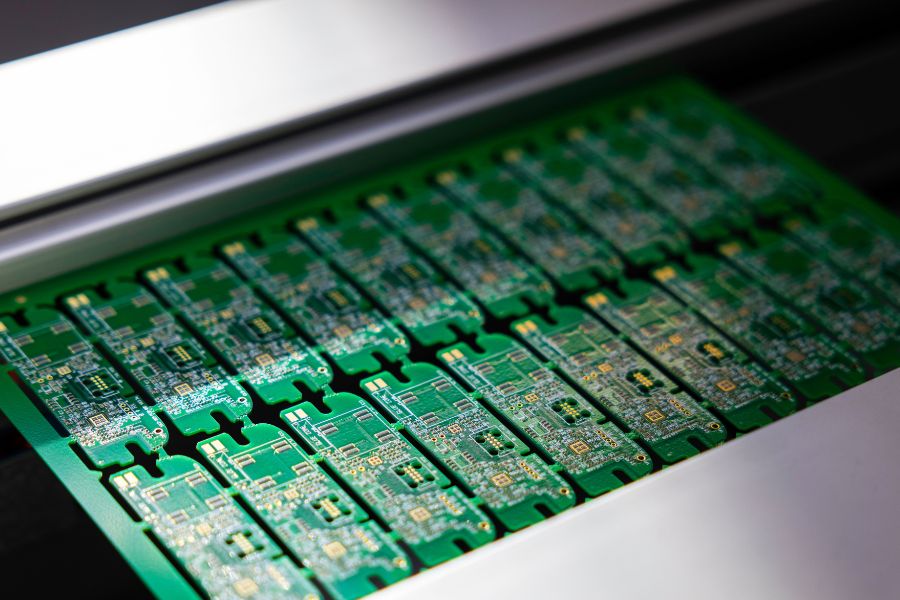

With the growing need for sophisticated electronic products, your application can benefit from using both Surface Mount Technology (SMT) and Through Hole Technology (THT), known as ‘mixed technology’.

Our expert team has extensive experience in assembling multi-layer PCBs, which are intricate electronic circuit boards with multiple conductive layers.

Mixed Technology Assembly allows for the best of both SMT and THT, while multilayer PCBs accommodate complexity and achieve space efficiency.

Contact our specialist team to discuss which PCB type and assembly technique is the perfect fit for your product

Wave Soldering vs Hand Soldering

Wave Soldering for reliable joints

If your assembly requires conventional THT mounted components, our team will use a wave soldering machine to automate the process. In a matter of seconds, through-hole components are soldered to the printed circuit board, resulting in mechanically and electrically reliable joints.

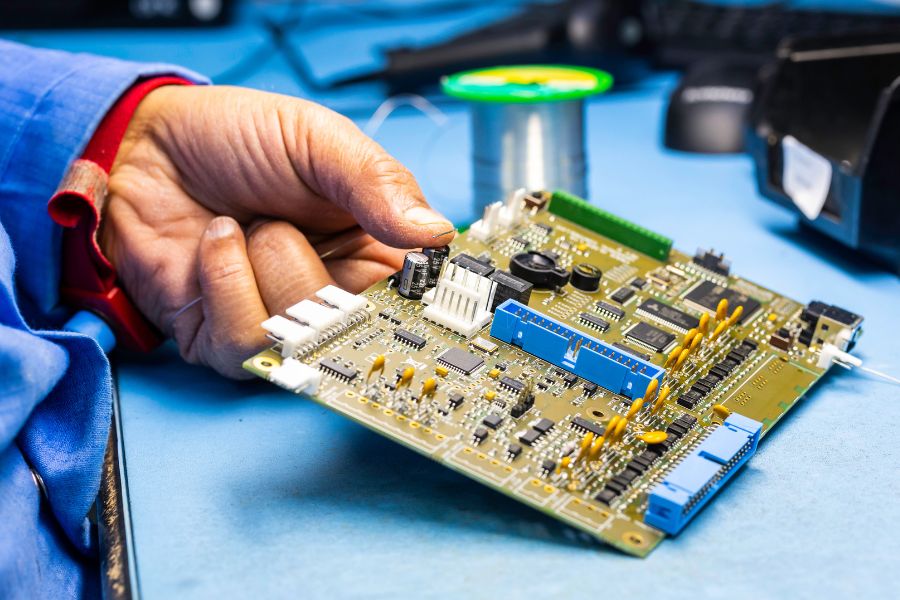

Hand Soldering for intricacy

Hand Soldering is used on components that cannot be wave soldered. A process requiring exceptional craftsmanship and levels of attention, our soldering engineers use a hand-held soldering iron, selecting suitably sized tips to form joints that meet the exact requirements of your assembly.

Soldering is a pivotal step in the PCB assembly process, entailing the securely attachment of electronic components to the circuit board using either wave soldering or hand soldering.

The MPE team will provide guidance on the most suitable techniques to enhance the performance of your specific assembly.

New Product Introduction

All new products go through our New Product Introduction (NPI) process following receipt of your order with us. The NPI process encompasses the entire assembly production process including:

Preliminary product design

Primary prototyping

Product development

Secondary prototyping

Pre-production manufacturing

Complete manufacturing

From our very first pre-production meeting, you’ll experience how our NPI process is designed to foresee and resolve potential issues before starting PCB assembly manufacturing. Our hands-on approach ensures a smooth production process, reducing potential delays.

End of Life Notifications

Securing the continuity of your PCB assembly production means partnering with a contract electronics manufacturer with an established component replacement plan for when End of Life (EOL) notifications, aka Product Discontinuance Notices (PDNs), are issued, advising of the discontinuation of a material or part.

MPE’s solid relationships with approved suppliers ensure that we promptly receive EOL notifications affecting the parts we purchase. Our experts thoroughly assess each notification, keeping you informed if components crucial for your PCB assembly are scheduled for discontinuation.

Once our team receives a notification, we explore your options, such as initiating a Last Time Buy (LTB) order. This allows our team to place final orders with the manufacturer and inform them of the order deadline. We’ll also review alternative parts listed in the notification, assessing their suitability for your PCB assembly, and, if needed, request samples from the manufacturer.

Surface Mount Technology

Learn how SMT can elevate your product performance

PCB Assembly

Precise, reliable PCB assembly to your exact requirements.