Automated Optical Inspection Services

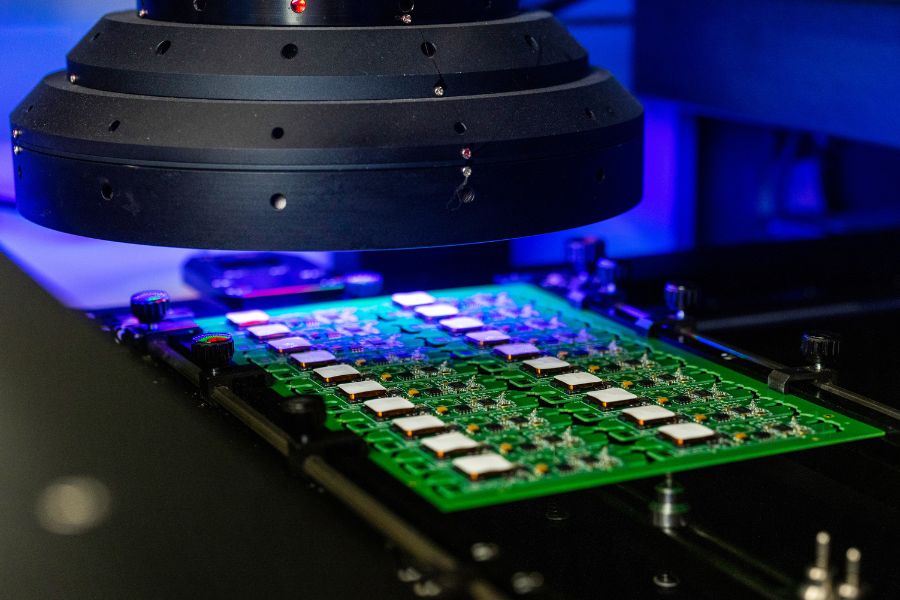

High-Precision Automated Optical Inspection for PCB Assemblies

In the fast-paced world of electronics manufacturing, ensuring that PCB assemblies meet the highest standards of quality is essential. As a leader in the industry, MPE is committed to delivering exceptional reliability and precision through our state-of-the-art Automated Optical Inspection (AOI) systems. Our AOI technology, combined with expert services, allows us to inspect every PCB assembly, regardless of order size, ensuring optimal performance. This commitment to quality guarantees the highest level of accuracy, stability and consistency, meeting the needs of purchasing managers and product designers alike.

What is Automated Optical Inspection (AOI)?

Automated Optical Inspection is a vital technology used in PCB assembly to enhance the quality control process by using advanced imaging systems to inspect PCB assemblies for potential defects. AOI systems offer a non-contact, fast and accurate method for examining assemblies, ensuring that every component is correctly placed and meets the necessary specifications. This level of scrutiny is essential in preventing costly errors and failures in electronic products.

Key Benefits of Automated Optical Inspection

High accuracy and consistency

AOI systems are renowned for their precision in detecting defects, ensuring that each PCB assembly meets the highest standards. At MPE, every surface mount assembled PCB undergoes inspection using AOI technology, delivering a high level of precision and identifying potential faults at this initial inspection stage.

Fast and efficient inspection

A key advantage of AOI is its speed. The ability to quickly scan and analyse each PCB assembly allows for rapid feedback and corrective action, minimising downtime and ensuring that production schedules are maintained.

Non-contact inspection process

The non-contact nature of AOI ensures that delicate components are not damaged during the inspection process. This feature is crucial for maintaining the integrity of the PCB assembly and ensuring that all components function as intended. By using AOI, MPE can deliver PCB assemblies that meet the highest quality standards without compromising the physical integrity of the components.

Enhanced quality control

AOI autonomously scans each assembly, detecting a wide range of potential defects, including issues with component alignment and soldering quality. This thorough inspection process ensures that every assembly leaving our facility meets the stringent quality requirements of our clients.

Why Choose MPE for Your PCB Needs?

Our commitment to using Automated Optical Inspection technology in every build ensures that we consistently deliver products that meet industry standards. For purchasing managers and product designers looking for superior quality PCB assemblies, MPE offers the most reliable solution. Our investment in advanced AOI technology, coupled with our commitment to quality and precision, makes us the ideal partner for your electronics manufacturing needs.

Surface Mount Technology

Learn how SMT can elevate your product performance

Through Hole Assembly

Enhanced strength and security with this preferred option.

FAQs

Can AOI detect all types of defects in PCB assemblies?

While AOI is highly effective at detecting common defects such as misaligned components, poor solder joints, and incorrect placements, its ability to detect certain complex or microscopic defects depends on the system’s capabilities and the quality of the imaging.

At MPE Electronics, we consistently meet industry standards by investing in advanced AOI technology, ensuring we remain at the forefront of defect detection and continue to lead the UK industry alongside our industry peers.

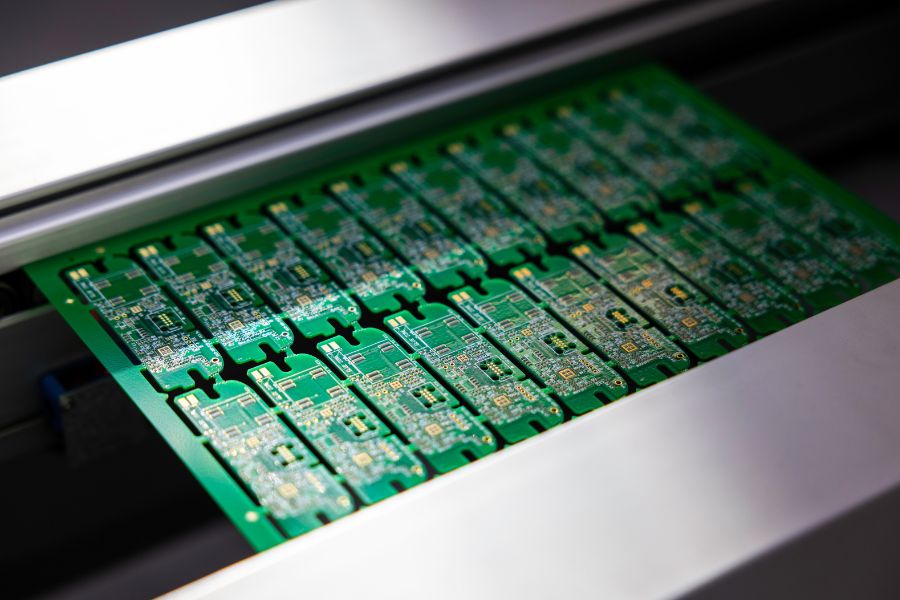

Is AOI suitable for all types of PCB assemblies?

Yes, AOI is suitable for a wide range of PCB assemblies, from simple to complex designs. It is particularly effective for high-volume production, where consistency and accuracy are essential.

What is the difference between CCD and AOI Technology?

Both CCD cameras and AOI systems are used in PCB assembly lines, but their roles differ significantly. CCD cameras capture high-resolution images for manual or semi-automated inspections, requiring human interpretation to identify defects. AOI systems, on the other hand, use advanced imaging, pattern recognition and algorithms to automatically detect issues in real-time, offering greater speed and precision than CCD cameras. The level of human intervention is significantly reduced, ensuring a faster inspection process.

What are the benefits of AOI?

- Automated and Precise: AOI systems autonomously identify defects such as misaligned components, incorrect soldering and placement errors with high precision.

- Speed: AOI offers real-time, rapid inspection, significantly improving the efficiency of large-scale production lines.

- Consistency: Provides consistent quality control, greatly reducing the risk of human error and ensuring each assembly meets our exacting standards.

MPE prioritises AOI technology to deliver reliable, expert inspection solutions, ensuring every PCB assembly meets the highest quality standards with accuracy and efficiency.

Is CCD an alternative to AOI?

Charge-Coupled Device (CCD) cameras capture high-resolution images of PCB assemblies. These images are used for manual or semi-automated inspections, where human interpretation is needed to identify defects. CCD offers:

- Lower Initial Cost: Generally more affordable than AOI, making them accessible for simpler inspection tasks.

- Simplicity: Easier to set up and can be used for basic inspections that do not require detailed analysis.

- Flexibility for Custom Inspections: Useful for custom, non-standard applications where only basic visual checks are needed.