Surface Mount Technology

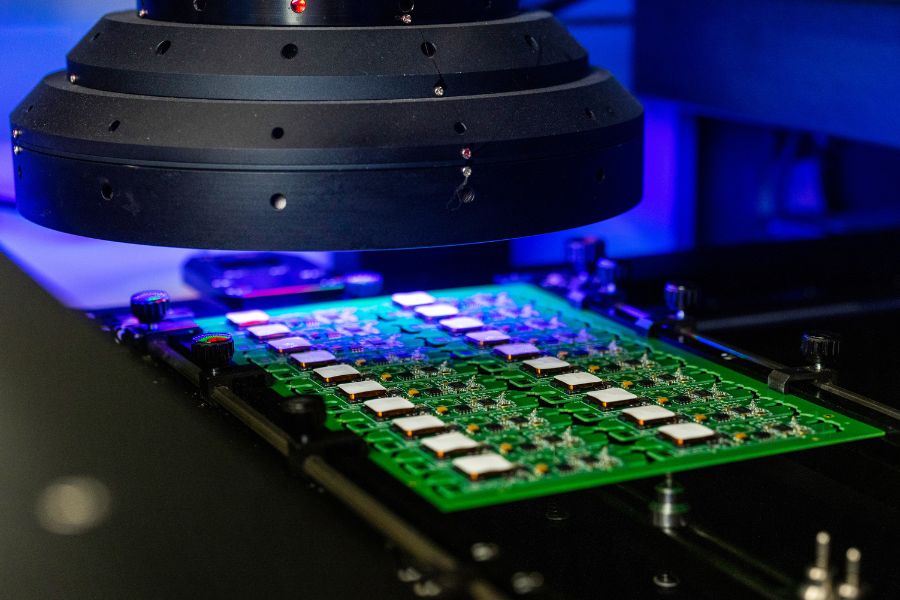

Elevate product performance with

Surface Mount Technology

Surface Mount Technology (SMT), where components are mounted directly onto the surface of printed circuit boards, is the most commonly used assembly process and particularly suited to more complex, customised PCB assembly designs owing to its many benefits:

Ability to place more components more closely together, enabling smaller, lighter and more powerful circuit boards

More cost-effective that Through-hole technology PCB assembly

More consistent soldering of components, reducing the potential for defects

Enhanced control over route traces, minimising mechanical heat and noise, improving product quality and performance

Read our Surface Mount Technology guide to learn more.

Mixed Technology Assembly & Multi-Layer PCBs

A combination of both Surface Mount Technology and Through Hole Technology (THT), known as ‘mixed-technology assembly’, is often employed to leverage the benefits of each method, while multilayer PCBs offer indispensable complexity and space efficiency.

With MPE’s multidisciplinary experience you can achieve:

Single side mixed assembly, whereby a single-side PCB undergoes both SMT and THT assembly processes

One side SMT and one side THT, whereby one side of the PCB is an SMT assembly and the other is a THT assembly

Double side mixed assembly, whereby both sides undergo both SMT and THT assembly processes

Our engineers use the Gerber data pack, that includes an XY data file, to program our pick-and-place machines with precision, ensuring compliance with IPC-A-610 class standards.

New Product Introduction

New Product Introduction (NPI) is an essential part of the work we do with our customers. Together we will map out the electronics NPI procedure, taking your product design from initial working prototype through to a refined and reproducible final product.

The NPI procedure requires a significant investment of time and resources, detailing the production phases required to meet your specification and how this results in a finished product for the marketplace.

This detailed process planning is an aspect of MPE Electronics service that is founded on trust and open communication with our clients.

When partnering with us, you can expect a meticulous NPI service involving:

Initial product design

Primary prototyping

Product development

Secondary prototyping

Pre-production manufacturing

Full manufacturing

Learn more about our NPI procedure and how it supports your product development process here.

End of Life Notifications

End of Life (EOL) notifications, or Product Discontinuance Notices (PDNs), alert manufacturers to materials or parts discontinuation.

MPE’s robust relationships with approved suppliers ensures the prompt receipt of EOL notifications for any parts we usually purchase.

Upon receipt of an EOL notification, we explore available options, such as initiating a Last Time Buy (LTB) order, allowing our team to place final orders with the manufacturer and communicate the order deadline. We also review alternative parts listed in the notification, assessing their suitability for your PCB assembly and request samples as needed.

Having carefully assessed each notification and the alternatives, our expert team will promptly inform you of any components for your PCB assembly that are affected and our intended plan to mitigate the discontinuation.

Through Hole Assembly

Enhanced strength and security with this preferred option.

Automated Optical Inspection

We commit to AOI 100% of every build after SMT.