Product Continuity Management

Product Continuity Management that sustains the success of your product

Product Continuity Management (PCM) is a vital element of PCB assembly and box build assembly. MPE’s tried and tested New Product Introduction (NPI) process includes provisions to enable us to mitigate any risks to the continuous production of your PCB assembly by identifying and addressing any potential issues before manufacturing begins.

Preparing for manufacture

As soon as you have submitted your sales order, you will begin to experience the positive impact that our PCM process brings to your product development.

All teams relevant to your PCB assembly design are directly involved in a focused pre-production meeting, in which our experts review your PCB assembly data. We pore over the details of the information supplied, including the Bill Of Materials (BOM), drawings, work instructions and test specifications, to assess and ensure that we have all the essential information required to successfully manufacture your PCB assembly.

We discuss the production processes involved to make certain that we have all the essential skills, equipment and tooling required for your PCB assembly and/or Box Build. Our experts will be in close contact with you throughout, to address any queries prior to production. You will also receive direct feedback relevant to the design of your PCB assembly or challenges that we may face in its manufacture.

While MPE does not have in-house design capabilities, we are committed to supporting your product development process by managing the outsourcing of your design on your behalf, to ensure your PCB assembly is designed for manufacturability.

Contact our specialist team to discuss your PCB assembly & Box Build requirements

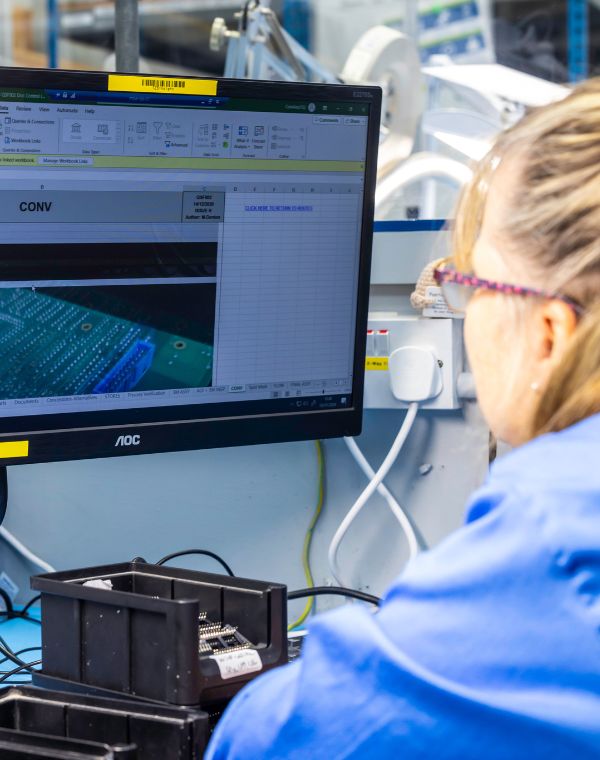

Accurate inventory control

We understand the trust placed in our ability to produce PCB assemblies on time, without compromising on quality.

MPE maintains accurate inventory of frequently used resistors and capacitors, ensuring sufficient buffer stocks are in place through strategic collaboration with our suppliers. We carry out a thorough goods inspection and allow for any potential delivery delays without negatively impacting our agreed PCB assembly production schedule.

We buy directly from approved distributors and suppliers to mitigate the risk of inadvertently purchasing counterfeit parts.

End-Of-Life notifications

End of Life (EOL) notifications, also known as Product Discontinuance Notices (PDNs), inform manufacturers that a specific material, part or component will no longer be available for sale or receive further support. To ensure the continuity of your PCB assembly production, having a contract electronics manufacturer who can put in place a realistic component replacement plan is crucial.

MPE has built strong relationships with our approved suppliers, who readily share EOL notifications with us when the part we have historically purchased is affected. Our experts carefully review each notification before informing you if the components used to produce your PCB assembly are to be discontinued.

Together we then discuss your preferred course of action, such as implementing a Last Time Buy (LTB) order, enabling our team to enter final orders with the supplier and advise you of the date by which we must receive your order. We also review the notification to consider any alternative parts our supplier has listed, to gauge their suitability for your PCB assembly, and will request a sample as required.

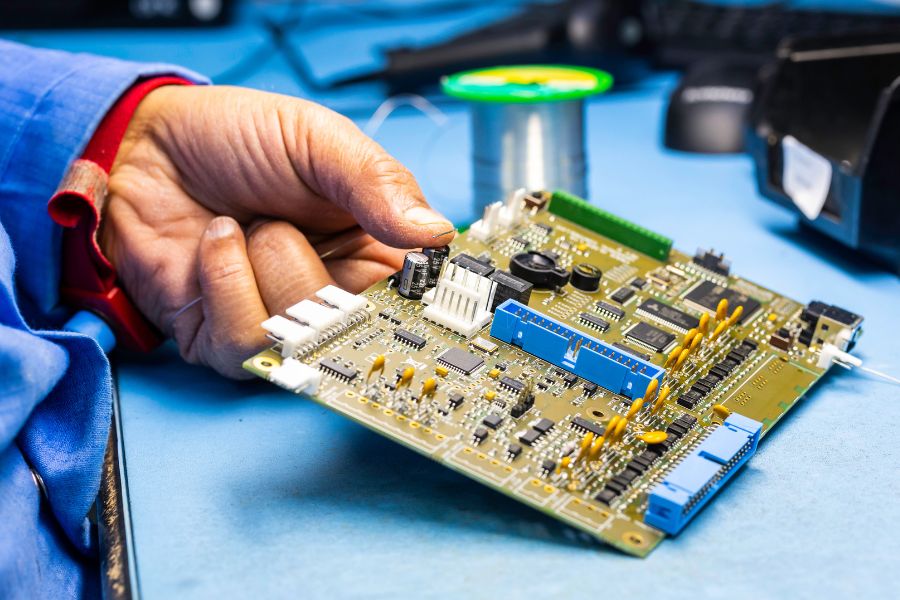

PCB Assembly

Precise, reliable PCB assembly to your exact requirements.

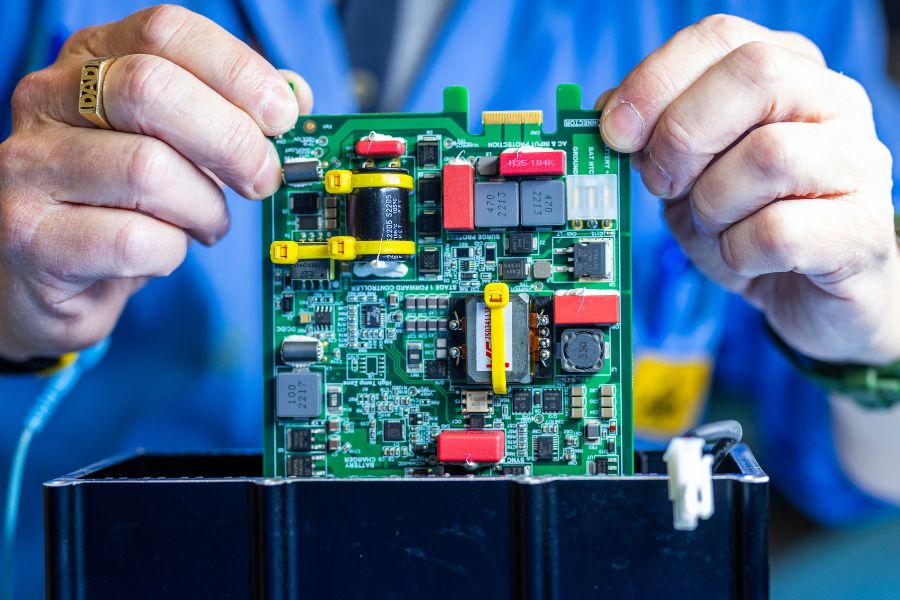

Box Build Assembly

Optimise your supply chain with our turnkey assembly service.