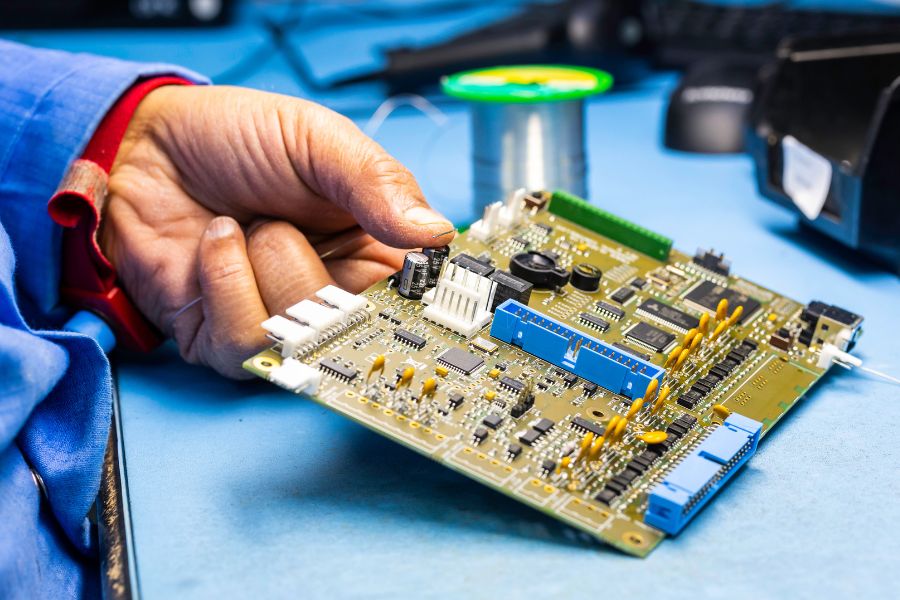

PCB Prototyping

Move forward confidently with PCB prototyping

The design and development of your electronic product calls for a PCB assembly partner with the capability, expertise, flexibility and resources to help you prove your product design during the pre-manufacture stage. A PCB assembly prototype empowers you to keep control of product quality and enhance production cost efficiency.

Integrate PCB prototyping seamlessly into your product development process

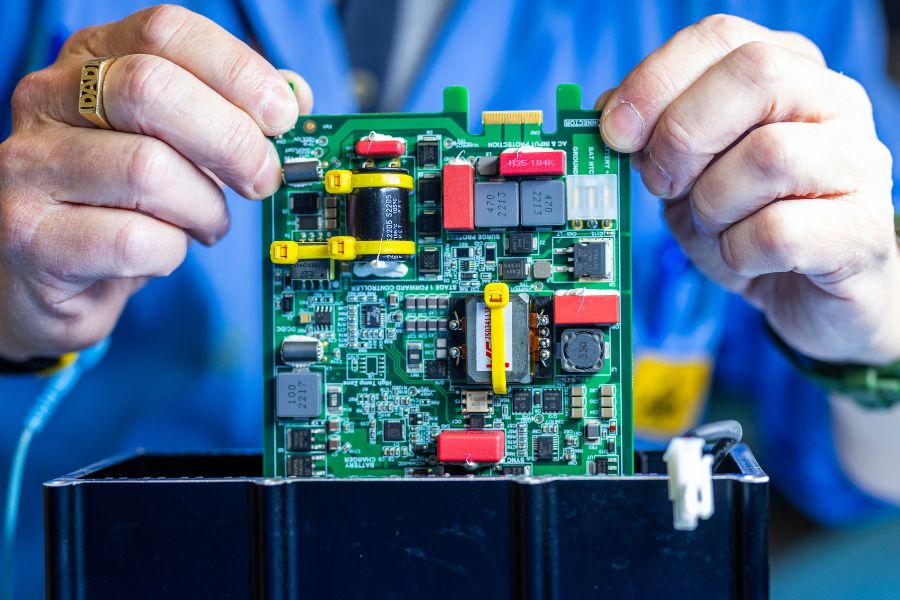

Whilst it is not a standalone service we offer, our team has the experience and essential skills to include both product and PCB prototyping as part of our PCB assembly and Box build assembly services.

We can include prototyping as part of our New Product Introduction (NPI) service offering to support each stage of your electronic product design and development process:

Product design

Primary prototyping

Product development

Secondary prototyping

Pre-production manufacturing

Full manufacturing

You can access our services at any stage of your design and development process. We have the flexibility to adapt to your needs to deliver high-quality PCBs for design prototypes and final products as required.

PCB prototyping guarantees quality

MPE Electronics uses a prototype PCB to detect flaws early on in the design and development process, precisely identifying which components require adjustment. All of our prototypes undergo rigorous testing to ensure reliable functionality.

We run prototype batches to:

prove your design

evaluate if your design is manufacture-friendly

discover relevant information to support redesign or product upgrade queries

ensure that we have all the relevant in-house skills, tooling and equipment required to efficiently manufacture your product and guarantee superior quality

Learn more about what our PCB assembly service includes in more detail here.

PCB Assembly

Precise, reliable PCB assembly to your exact requirements.

Box Build Assembly

Optimise your supply chain with our turnkey assembly service.