Electronics Box Build Assembly Services

Best in class full box build assembly

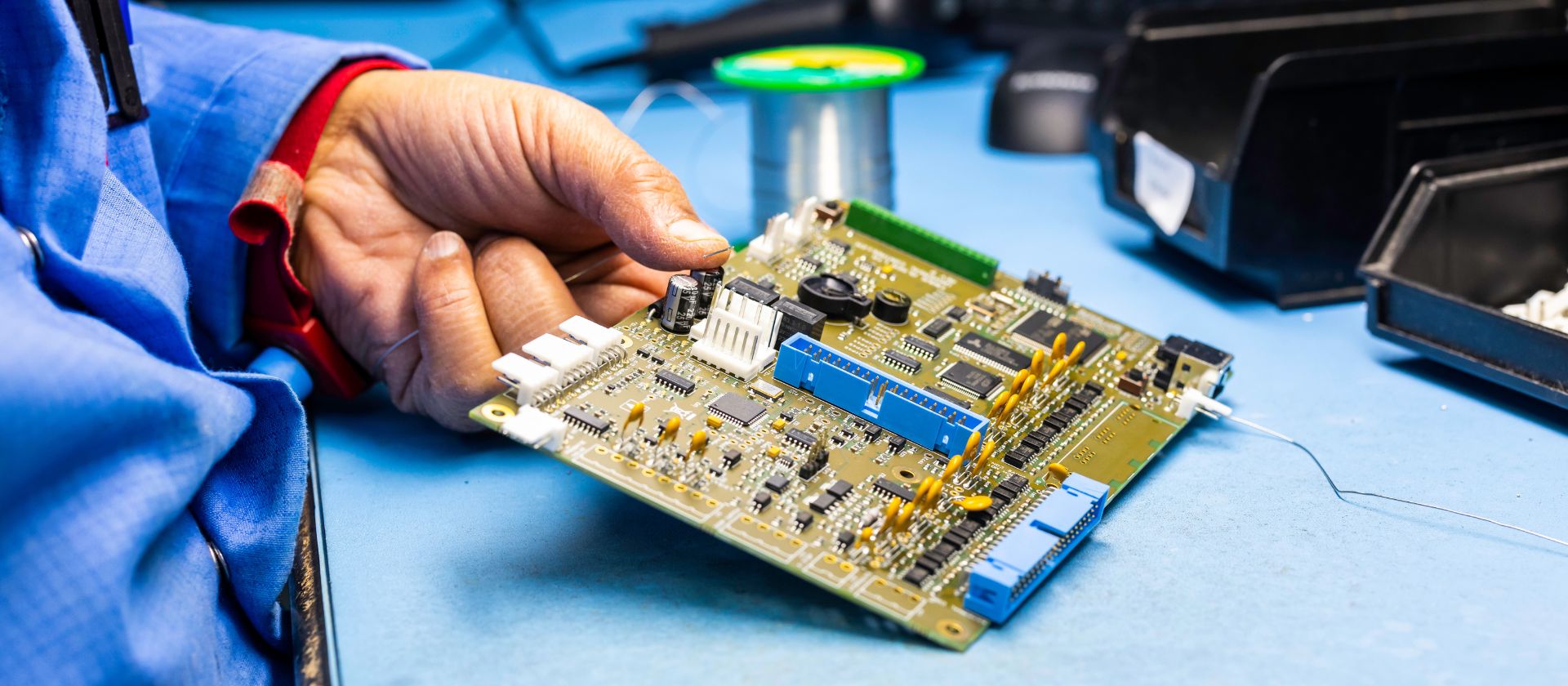

At MPE Electronics, we are more than just a contract electronics manufacturer. We don’t just produce high quality PCB assemblies, we take your project further by delivering fully integrated, finished products with precision and efficiency.

What is a box build assembly service?

Full box build assembly

Box build assembly, also known as full box build, mechanical assembly, turnkey assembly or product assembly, is the mechanical process of taking assembled printed circuit boards and integrating them into cases, enclosures or chassis.

The comprehensive integration of your PCB assemblies can involve anything from the installation of sub-assemblies or modules, and/or the fitting of cable harnesses and additional mechanical components.

Packaging, labelling, warehousing and distribution

Box build assembly services also encompasses packaging and labelling, warehousing and distribution, including delivery direct to your customers, meaning that your final product reaches your target market faster, with significantly reduced potential for delays or interruptions.

Quality control and risk management

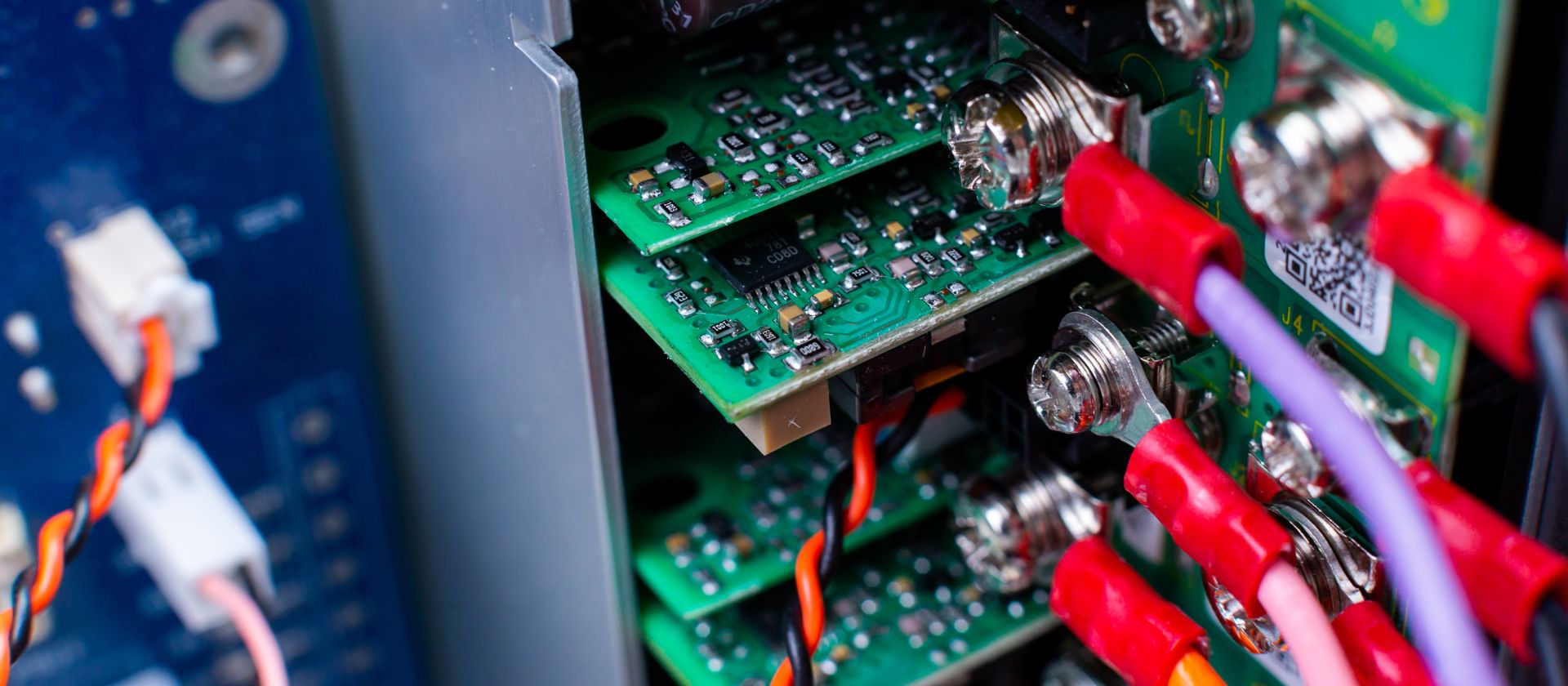

As with our PCB assemblies, your box build assembly will be put through a range of agreed testing procedures to guarantee that it is fit-for-purpose and performs to your specifications.

Involvement in the design stage of your PCB assembly all the way through to the box build itself ensures our expert team has a thorough understanding of your specifications.

We can also rigorously control quality and detect any potential issues using our New Product Introduction process, reducing the risk of error and the need for rework.

What services are included in a full box build solution?

A full box build solution encompasses various services, including:

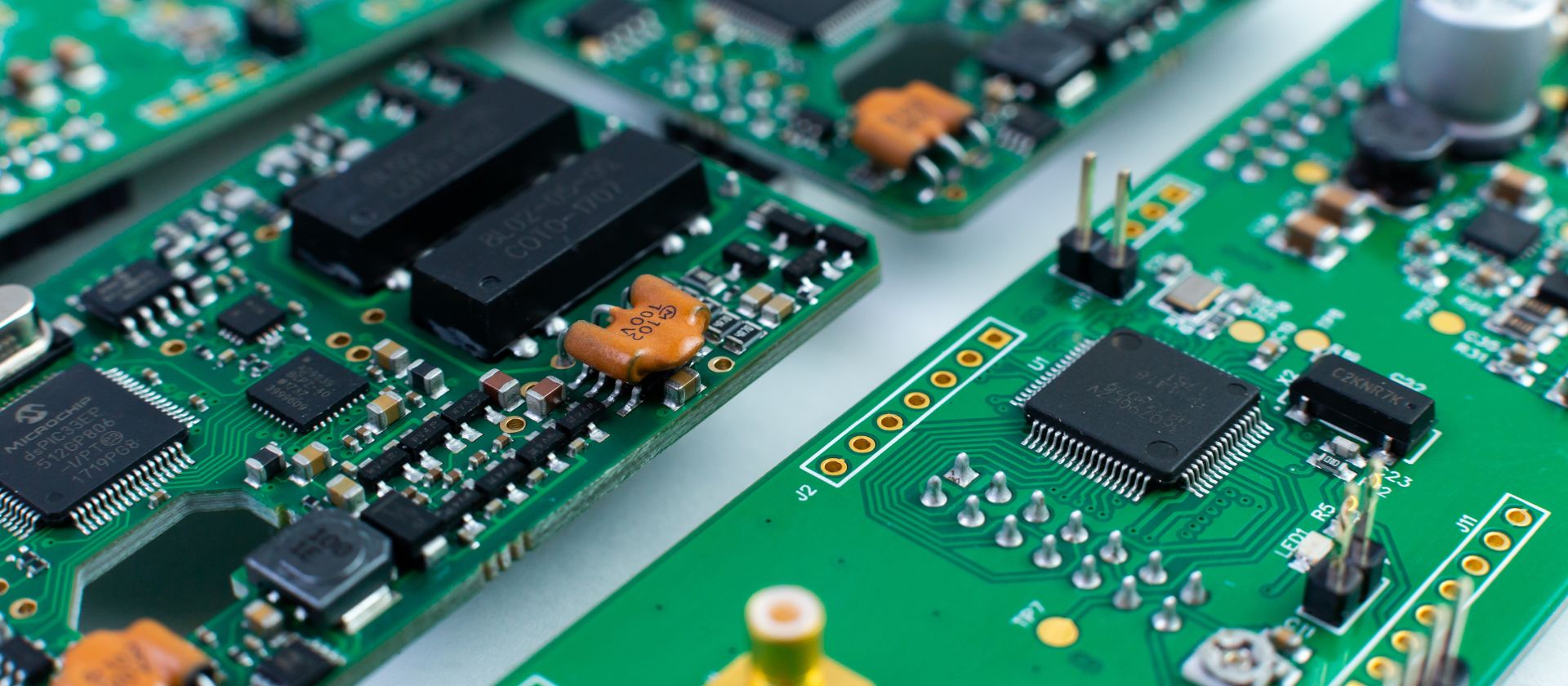

PCB assembly

Sub-assembly and enclosure installation

Cable harness and wiring loom assembly

Device firmware programming and configuration

Functional testing and quality assurance inspections

Product serialisation and traceability

Packaging, labeling, warehousing and distribution

A Closer Look at Our Box Build Assembly Services

FAQs

What are the benefits of outsourcing electronics box build assembly?

Outsourcing box build assembly to a specialist provider like MPE Electronics offers several advantages:

Simplified Supply Chain: Consolidates multiple manufacturing processes under one provider, reducing the complexity of managing various suppliers.

Cost Efficiency: Streamlines operations and minimises overhead costs associated with in-house assembly.

Quality Assurance: Ensures adherence to stringent quality standards through established testing procedures and certifications.

Faster Time-to-Market: Accelerates production timelines by leveraging the expertise and resources of the assembly partner.

Can box build services be customised to specific project requirements?

Yes, box build services are highly customisable to meet the unique needs of each project. Experienced assembly technicians and engineers work closely with clients to tailor the assembly process, component selection, testing protocols and packaging solutions, ensuring the final product aligns with exact specifications and industry standards.

How does MPE Electronics ensure quality in box build assemblies?

Here at MPE Electronics we uphold the highest quality standards in box build assemblies through stringent internal quality assurance procedures. This includes comprehensive testing of PCB assemblies, meticulous integration into enclosures and thorough final inspections.

As an official ISO 9001 certified supplier, we are committed to implementing and maintaining manufacturing and other processes, as well as the continuous training of our team, to reliably deliver an impeccable level of quality of products and services every time.

Outsource your electronics box build assembly to MPE

PCB assembly manufacturing

Learn More…

Potting and encapsulation

Learn More…

Coating

Learn More…

Testing

Learn More…

Packaging and labelling

Learn More…

Warehousing and traceability

Learn More…

Contact our specialist team to discuss your PCB assembly & Box Build requirements

“We have worked with MPE for 7 years and have found them to be able to [effectively manage] our fluctuating delivery requirements. MPE schedules component deliveries, including sub-assemblies and other materials specific to us, providing the product on time. The product quality has always been excellent which gives us peace of mind when shipping products around the world.”

Managing Director, Flow Meter Supplier

Logistics & Distribution

Guarantees your high-quality product arrives on time.

Electronics Packaging

Solutions that deliver products in the optimal condition.